IFFA 2019

MULTIPOND and MCA Process – an ingenious partnership when it comes to weighing meat

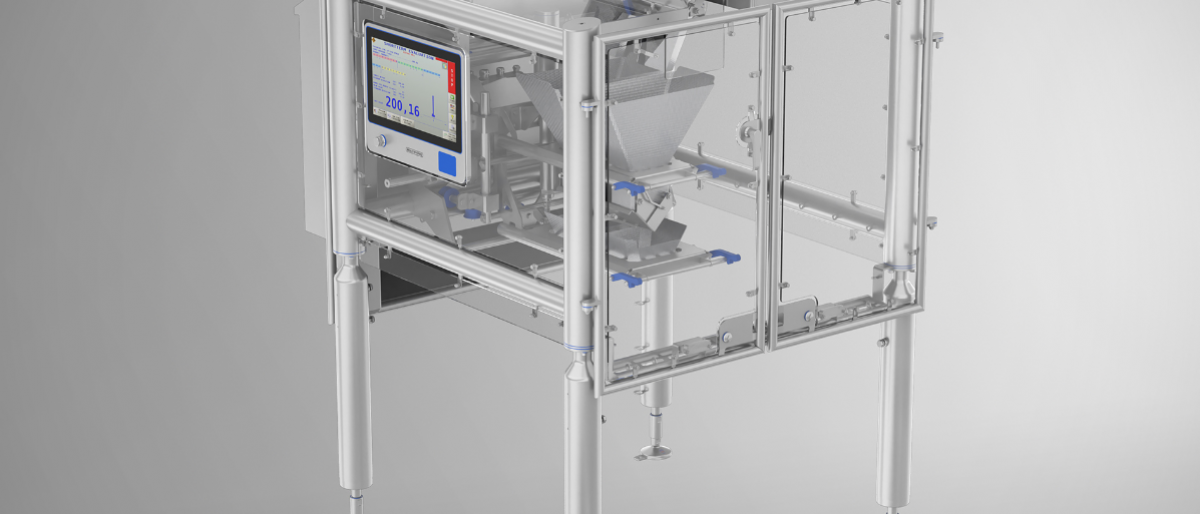

Precise, hygienic, quick: The new MULTIPOND protein weigher is setting standards in the meat processing industry. In collaboration with MCA, optimum teamwork between robot, patented feed conveyor and multihead weigher will be presented at the IFFA.

A robot feeds the patented claw conveyor from MCA Process with meat. The special feature of the mandrels integrated into the claw conveyor allows pieces of meat to be picked up without causing major damage to the surface structure. And so the product is conveyed to the weigher pre-separated and under control, which in turn creates the basis for a uniform product feed to the weigher.

Weighing meat mechanically definitely presents great challenges. Animal products are very sensitive, they adhere to numerous surfaces and have to meet the most stringent hygiene requirements. In refining the MP-16-3800-1250-J multihead weigher, MULTIPOND has created the optimum solution for the meat industry: The benefits of the proven J Generation system, where hygiene and leak-tightness of the machine are the main concerns, are combined with a multitude of optimizations especially for the meat sector.

Intelligent reactions from the weigher

In order to improve the product flow to the distribution cone and feed trays even further, the weigher is equipped with two special 3D cameras. These cameras tell the software how the products are arranged on the distribution cone and feed trays. Using this information, the multihead weigher automatically implements measures to ensure uniform product distribution and to resolve any problems, such as pieces of meat that have become stuck. Fragmented product distributions on distribution cone and feed trays are diagnosed and resolved accordingly.

Highest hygiene standards in combination with highest IP protection class

The protein weigher satisfies the toughest hygiene requirements worldwide. The weigher is completely designed in accordance with USDA and EHEDG directives, creating the basis for simple, fast and reliable cleaning. Protection class IP69 is the ideal basis for the use of high-pressure cleaners. MULTIPOND is the only manufacturer of multihead weighers anywhere in the world that achieves this protection class without generating overpressure in the machine. Compressed air is not required.

The weigher is designed for an output of up to 100 weighings per minute, depending on application, product and target weight, with the highest degree of accuracy.

Geared up for the growing meat market

With all its benefits, the new protein weigher is predestined for use in the meat processing industry. There is, without doubt, a demand: The meat market continues to grow, especially in South America. According to a report in the trade journal, in Brazil alone the export volume of beef has quadrupled in the last six years to reach four billion US $. At the same time, consumer demands for the hygienic processing of foodstuffs are growing. Thanks to its innovative product range, MULTIPOND enjoys an excellent market position – with quality high-performance technology “Engineered and Manufactured in Germany”.

THE LATEST NEWS