MULTIPOND consistently implements trend towards motorized drives in its product transfer system

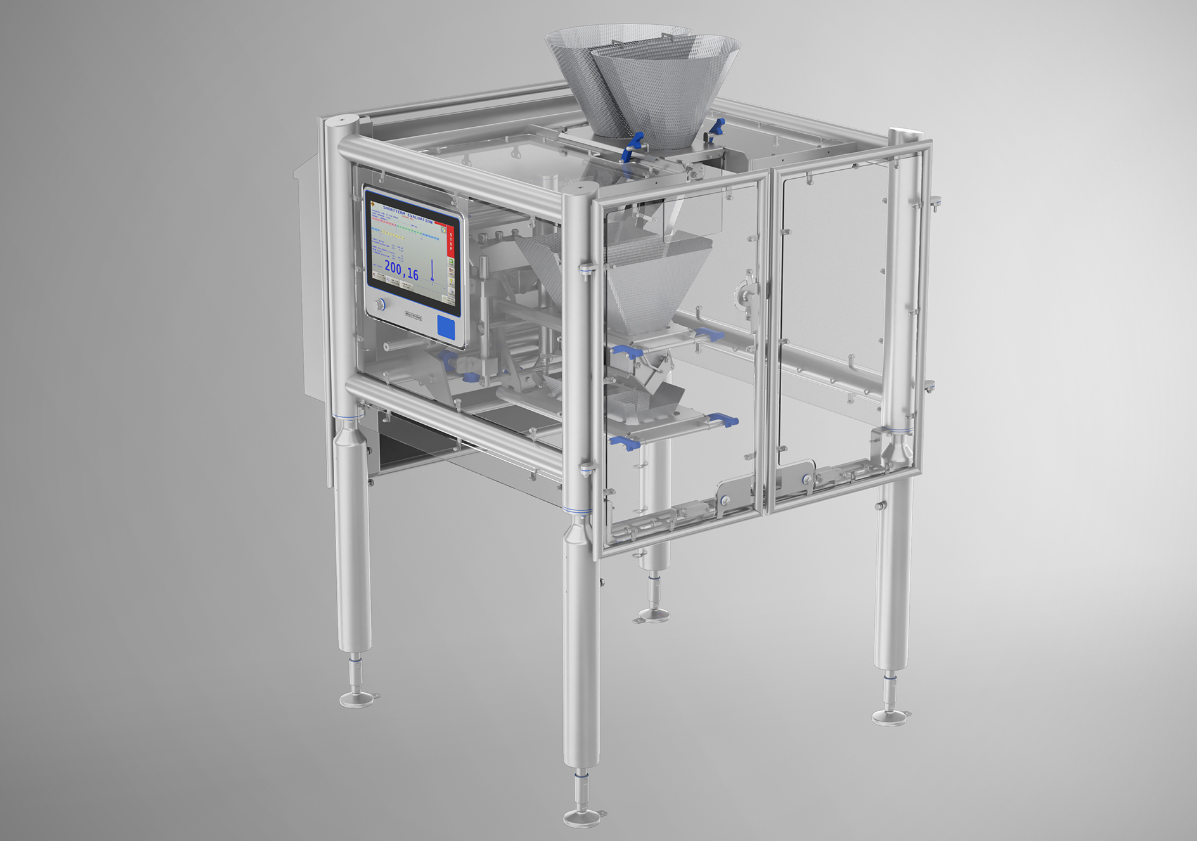

The product transfer system presented at interpack 2021 can be combined and synchronized with various horizontal packaging machines from renowned manufacturers. As a result, the continuous, revolving filling unit achieves both a higher output and a higher line capacity.

MULTIPOND always works with state-of-the-art technology to develop its product transfer systems and combination weighers. In terms of capacity, operational reliability and wear, the use of motorized drive components in the hygienic design offers significant advantages over conventional systems involving pneumatic components:

- Follow-up costs: Compressed air, an extremely expensive commodity due to the high hygiene requirements in the food sector in particular, is not required to operate the machine.

- Flexible: Motorized systems are adapted to trays of different heights without a problem. One system can be used for a multitude of different trays

- Gentle: The continuous adjustment of the motor speed reduces the load on the components. Allowing premature wear in the process.

Adapted to the MULTIPOND weighing system standard, we take every precaution to ensure the best possible level of hygiene. The use of circular tube frames avoids unnecessary corners in which germs and bacteria can accumulate. Any liquid remaining after the cleaning process drains out over sloping surfaces. The front side of the product transfer system was designed to allow easy access to the format parts. This offers significant advantages, especially in applications that require intense cleaning. The systems consistently conform to protection class IP69.

MULTIPOND Wägetechnik GmbH is a highly-specialized custom machine builder for multihead weighers in the food and non-food sectors. Ever since the company was founded in 1946, its secret of success has been based on maximum precision and speed, as well as maximal product quality. The high degree of vertical integration with in-house hardware and software development, as well as research, at the headquarters in Waldkraiburg, Germany, guarantees the quality standard of this owner-managed, traditional company. All main components of the weighing system, from the load cell to the weigh hopper, are produced and precisely matched to one another in-house. The over 300-strong, international team from Germany, France, Great Britain, The Netherlands and the USA encourages innovations and technical perfection in close cooperation with the customer.

THE LATEST NEWS