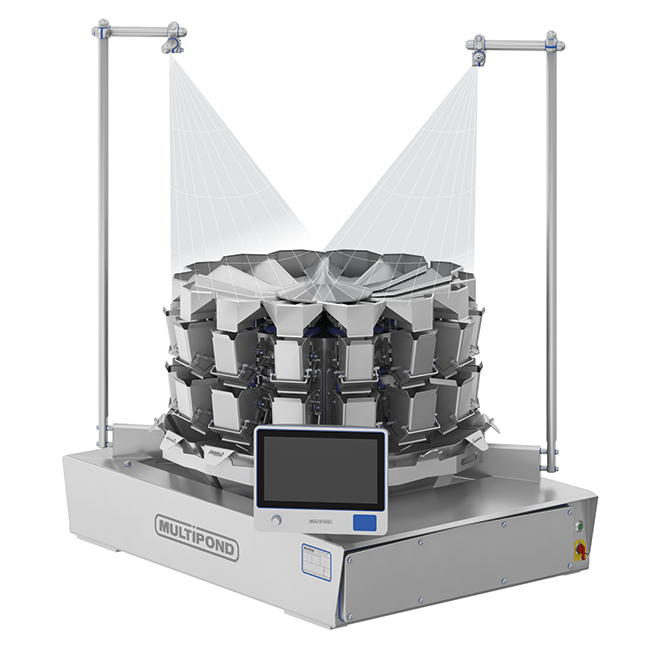

EYES

FOR YOUR WEIGHER

Optimized feeding and continuous

product flow using the ARGUS camera

Keeping an eye on the optimum product flow

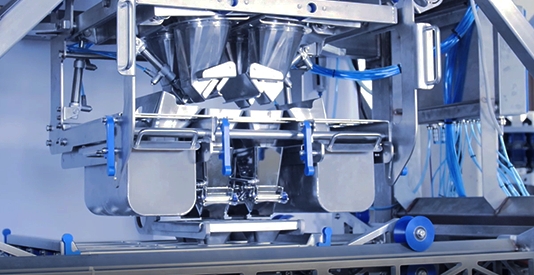

3D cameras deliver basic data for automatic adjustments in the feeding process. As does the ARGUS camera from MULTIPOND. The patented camera system optimizes the feeding of the product on the weigher, improves distribution and ensures controlled filling of the weigh hopper.

Faster, safer, more precise

The advantage of the camera-monitored weigher is clear to see: Thanks to the automatic reaction to the 3D image data, this system innovation guarantees controlled, precise filling of the weigh hopper. The product flow is optimized for shorter feeding times and fewer overfills. The result is a greater variety of combinations, even for products that are difficult to convey such as salad ingredients, cheese or meat. The benefit to the customer is a higher output, more accuracy and less giveaway.

- Higher output

- Higher accuracy

- Maximum process safety

Advantages of the ARGUS camera

shorter feeding times

through optimum product flow

controlled filling process

for even more precise results

Retrofitting

Can even be integrated into older weighers

Self-optimizing process

for uniform distribution

The ARGUS camera in use

Take a look at the projects we have already implemented and see for yourself. From salad to cheese to fish – benefit from the experience and knowledge we have developed over decades.

Our technologies

If you would like more information, start your inquiry: