Du sur-mesure pour vos systèmes de pesage

MULTIPOND Wägetechnik GmbH serves the food and non-food industry by drawing on decades of expertise. The focus is on achieving greater efficiency and economy by customizing the entire weighing process.

Giving an interview at Interpack, Philipp Kapser, Head of European Sales, describes how MULTIPOND helps its customers meet both current and future market requirements.

What are the challenges customers approach you with and why?

I would like to answer that question with an example from the clothing industry. Ready-to-wear clothing is designed to fit as large a cross-section of the population as possible. It stands to reason, then, that compromises have to be made in terms of the fit itself. A tailored suit, on the other hand, is created for your own body shape and any particular needs it may have. The individual details are a constant reminder that it was made exclusively for me.

MULTIPOND can be likened to a bespoke tailor, in that we do not offer a standard solution. Our weighing systems are precisely like this suit: It fits like a glove, fulfills the customer’s requirements for the best quality and may well be with him for life.

The growing demand tells us that this is exactly what customers appreciate about us.”

Supply bottlenecks and difficulties in procurement are a major burden for most companies. Some might think that custom products are hard to make. Why, then, is MULTIPOND achieving such growth?

“We have more people on our development team than most similar medium-sized machine construction companies. Most manufacturers are currently looking for alternatives and short-term solutions to ensure their ability to deliver. We, on the other hand, score points with our high degree of development and vertical integration throughout the entire production process. This independence from the procurement market gives us not only more calculable costs. We are able to adapt to changes in that market with the highest degree of flexibility and agility.

Especially in these difficult times, we believe in the importance of a dependable and long-term partnership of equals. The increased machine sales of over 40% in 2022 is testimony to this approach.”

The packaging industry often equates MULTIPOND with high prices. How do you explain this perception?

“Quite often, only the acquisition costs are considered when comparing offers.

At first glance, a customized product is usually more expensive than the standard solution.

But if we take a closer look, several other factors play a key role as well.

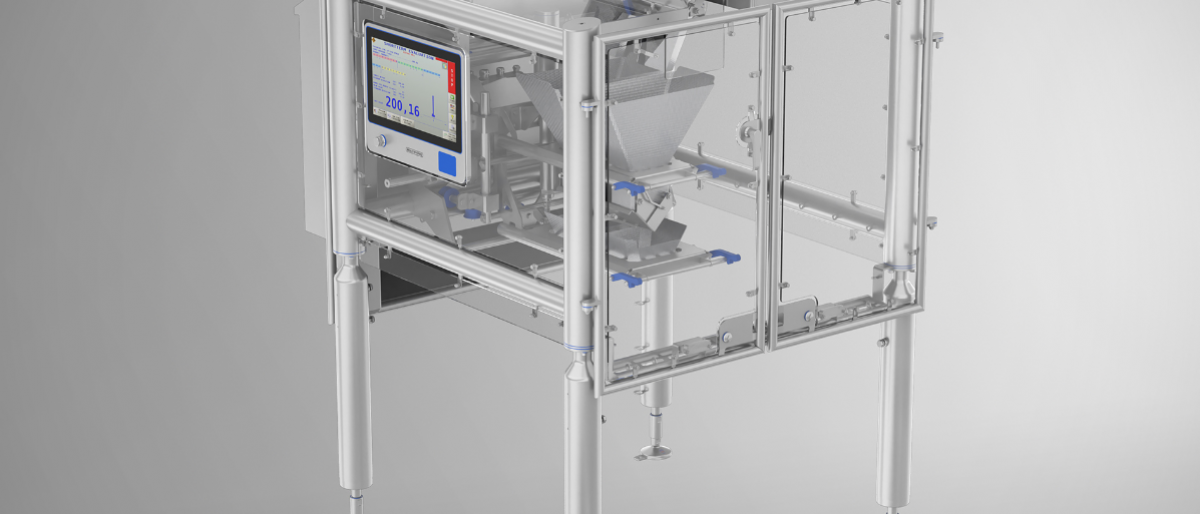

For example, our J-generation multihead weighers are set apart by their all-round hygienic design. This is the basis for fast and straightforward cleaning of the entire system while maintaining the highest hygiene standards. The fully automated calibration function and associated adjustment of the load cells ensure maximum availability. The significantly reduced downtimes this achieves lead to maximum utilization of production times for our customers. Our weighing systems, then, ensure an output that far outstrips the dump performance of a competitor product.

In addition, MULTIPOND is brilliant when it comes to accuracy. Our newly developed 18-head weighing system is considered a high-precision weigher and will be making its debut at Interpack. With a target weight of 5g, for example, we can guarantee a maximum deviation of 0.5%. This is equivalent to a difference of 0.025g – in effect, nothing at all. This allows our customers to minimize the amount of give-away and significantly increase the return on their investment.

Our high quality standards mean that we are often unable to compete with the price of cheaper suppliers. That said, a MULTIPOND weighing system usually pays for itself in the first year of use.”

And finally: You are talking about MULTIPOND weighing systems, which you compared to a tailor-made suit. What happens when that suit no longer fits? If the size or style changes?

“If the initial requirements do change, we adapt our weighers to the new production conditions. We talk to our customer to find the best possible solution that suits the new circumstances to perfection. No compromises are needed, because every weighing system can be converted to the new conditions through a wide variety of modifications.

Even machines that have been in operation for decades can be modified and the availability of spare parts is guaranteed. Of that we are especially proud!”

ACTUELLEMENT