As quickly

as possible

Continuously high performance adapted

to the product being weighed

Our strengths – High speed

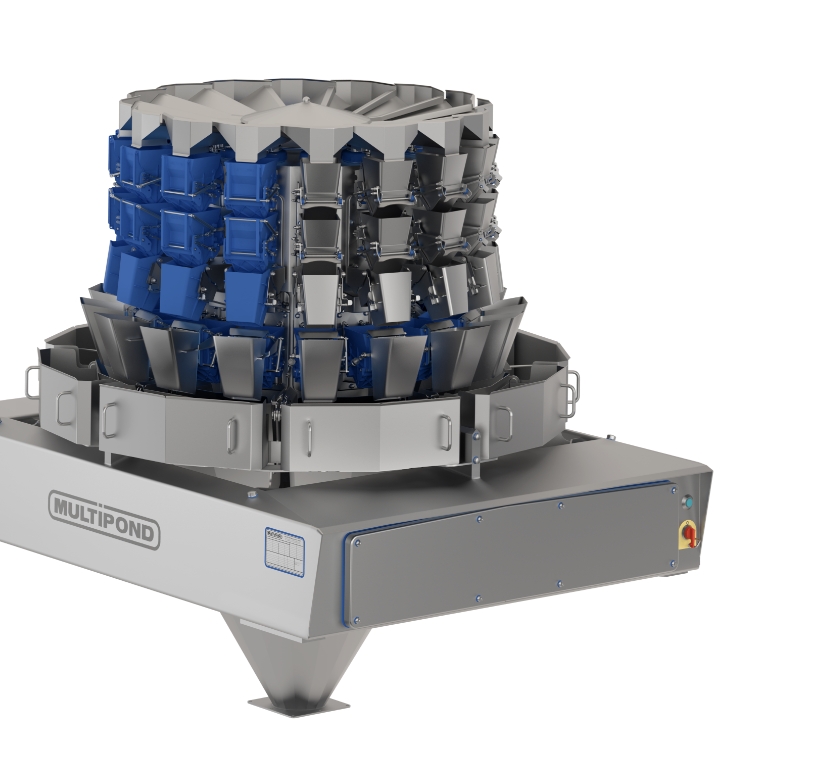

What exactly does high speed mean? High speed can be interpreted in many different ways. Not everyone sees high speed as achieving 900 cycles per minute – factors such as product, portion size or even the packaging machine also play a key role. It goes without saying that every multihead weigher from MULTIPOND aims to weigh every product at the fastest possible speed. That said, MULTIPOND offers special variations and additional equipment that are able to achieve a very high number of dumps and packed product units per minute.

The benefits of MULTIPOND to you

- Product optimally distributed on the weigher The product feed is controlled via preweighers, the product flow is evaluated and optimized using the 3D-ARGUS camera. Overfills are minimized, the number of possible combinations increased and higher package output is achieved.

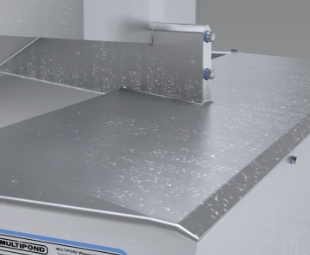

- Special surface finishes MULTIPOND offers various surface finishes, the properties of which are individually matched to the product. We have the right surface finish, whether to optimize gentle product handling or avoid product build-up.

- Fast signal processing Isolated from external influences, the weigher is able to deliver a fast, clean weighed result. This ensures fast weight recording.

- Automatic calibration Automatic calibration with integrated calibration weights guarantees maximum accuracy. The calibration process can take place during production to prevent production downtimes.

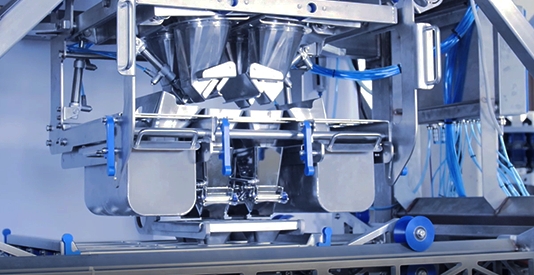

- Tailored handoff solutions The transition solutions developed by MULTIPOND ensure a perfectly synchronized process with the packaging machine. They pave the way for a secure and compact handoff and, above all, allow higher speeds.

- Continuous refinement of the weighing system With more than 75 years of experience, MULTIPOND has established a reputation as a leading, innovative manufacturer of multihead weighers. Over 5,000 weighing systems sold and successfully installed say it all. This long-standing experience and knowledge is the basis for continuous advancement of the weighing system.

Special variations and additional equipment

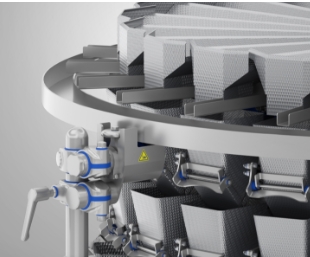

- MULTIPOND memory systems After the weighing process, each of the weigh hoppers fills two memory hoppers arranged beneath through specially developed swiveling funnels. The weighed partial portions are temporarily stored in these memory hoppers. The resulting greater versatility of combinations is the basis for the ultimate in precision and speed.

- MULTIPOND memory system with special dump function for overweights The concept is based on a standard memory weighing system where the outer memory hopper is replaced by a second swiveling funnel. Overweights can be discarded one sort at a time by the second swiveling funnel, while the weighing system can continue the weighing process without any loss of weighing performance or speed. This system is recommended especially for mixtures.

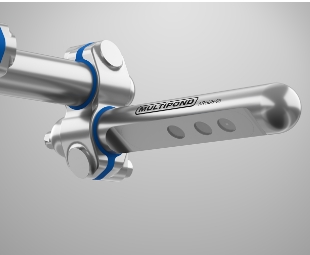

- MULTIPOND timing hopper concept (figure) Thanks to the new timing hopper concept, the transverse double duckmouth (DSEQ), the multihead weighers from MULTIPOND now crack a magical limit: with a target weight of 200 grams, up to 200 weighings per minute are possible.

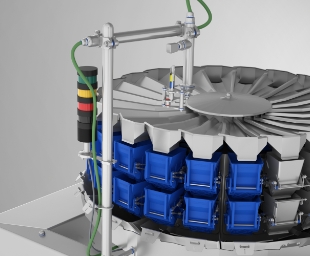

- MULTIPOND ARGUS CAMERA The patented camera system guarantees a controlled, precise filling of the weigh hopper. Optimizing the product flow achieves shorter feeding times, fewer overfills and hence a greater variety of combinations.

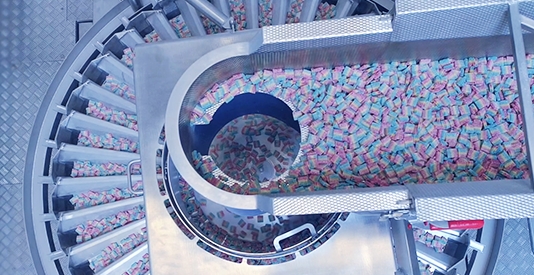

Our weighers in action

Take a look at the projects we have already implemented and see for yourself. From cereals to confectionery – benefit from the experience and knowledge we have developed over decades.

Optimally equipped – our individual expansions

Special requirements call for special solutions – whether for process safety, hygiene or internal quality standards, MULTIPOND offers exactly the right equipment for every multihead weigher.

Other technologies

If you would like more information, start your inquiry: