Precisely weighed

down to the nearest gram

Highest possible accuracy for the customer

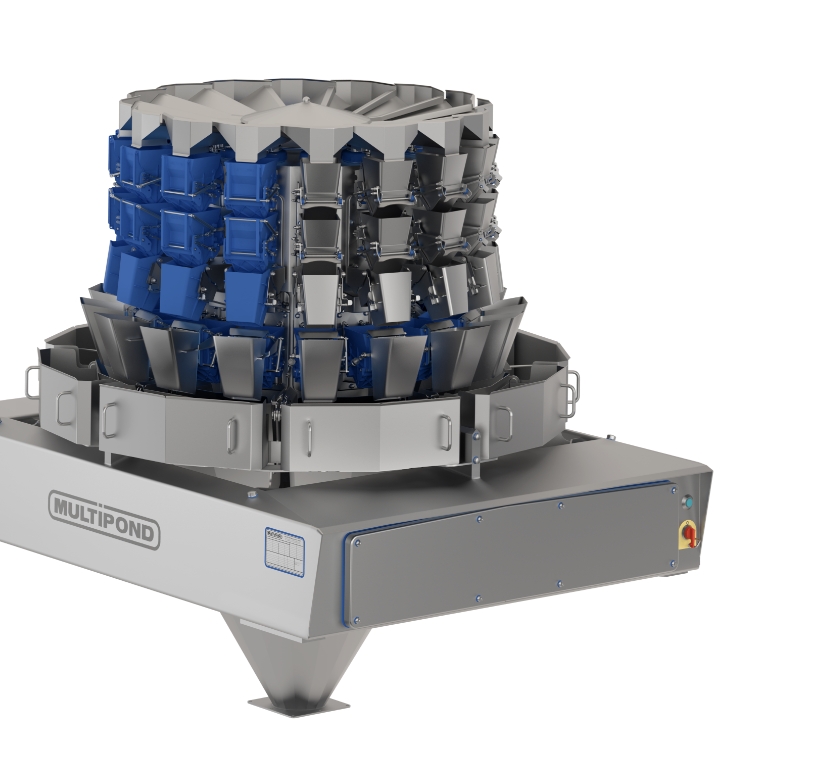

Our strengths – accuracy

Let us consider together for a moment what accuracy actually means. Accuracy is a concept that plays a key role in all areas of weighing technology. Accuracy means care, thoroughness, accuracy, compliance.

But what does accuracy mean at MULTIPOND?

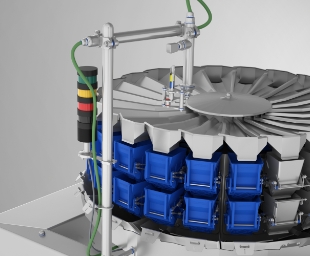

Three factors play a key role here. A weigher can operate with precision only when all these factors are harmonized and are closely matched. MULTIPOND therefore believes in a high degree of vertical integration at its location, in-house research & development of hardware and software components and a passion for technical solutions and the product itself.

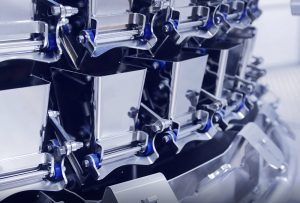

- PRODUCT FLOW

- Distribution cone and feed tray drive – we are known for the most powerful vibration drives on the market. With a self-optimization function, these drives guarantee a continuous, controlled product feed.

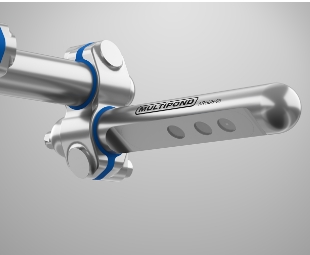

- Preweigher – controls and monitors the feed units. Just like the load cells – the heart of the weigher – this is developed and manufactured in a sophisticated production and quality assurance process. The preweigher is what guarantees consistent accuracies.

- ARGUS – Thanks to the automated response to the image data, this system optimizes the product flow and hence achieves a higher performance and greater accuracy. Especially when weighing difficult products such as cheese, salad and meat, our patented system measurably improves accuracy and ensures a higher output and minimal giveaway.

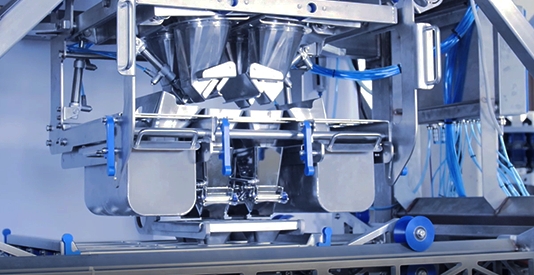

- VARIETY OF COMBINATIONS

The combining function is configured in the weigher software as a standard, basic function. Depending on the application, the target weights of one or more subcomponents are determined in the traditional combination mode. Functions such as mixing, counting and feeding can be selected as options. - VALUE LOGGING

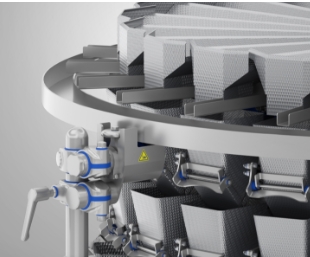

- Calibration – we are the only multihead weigher manufacturer to work worldwide with integrated mechanical calibration systems. On every weigher, the accuracy of a measurement is influenced by various factors such as ambient temperature, humidity, vibrations and so on. Over time, these factors distort the measurement. An error can be detected only by continually comparing the measurement results against a reference value, a calibration weight, and correcting any discrepancies accordingly. Only MULTIPOND weighers run this test automatically during production by means of integrated calibration systems. That’s how we make sure that every weighing operation is correct. As a result, there is no compromise on performance.

- Filter – For some considerable time now, we have used a digital filter system, which translates the confusion of zigzag vibrations into a “legible” transient oscillation curve. Depending on the set performance and the available transient time, the digital filter follows the transient oscillation curve step-by-step. If the peaks between are too high, the required standstill criterion has not yet been reached. A standstill is achieved only when all values are within a narrow range. The determined weight value can be used for combination.

Highest possible accuracy = Optimal product flow + high variety of combinations + precise value logging

Costs minimized over the long term

Here is a typical calculation to show that accuracy plays a key role in weighing technology:

Assumption:

- Production days per year: 280 days

- Daily production time: 16 hours

- Weighings per minute: 100 weighings

- Giveaway per weighing: 0.5 grams

- Product cost: 1.50 € per 100g

Total giveaway after one year:

13,440 TONS = 201,600 €

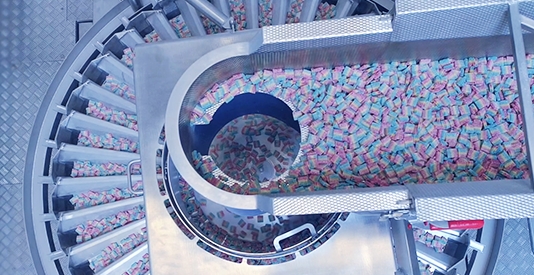

Our weighers in action

Take a look at the projects we have already implemented and see for yourself. From cereals to confectionery – benefit from the experience and knowledge we have developed over decades.

Optimally equipped –

Our individual expansions

Special requirements call for special solutions – whether for process safety, hygiene or internal quality standards, MULTIPOND offers exactly the right equipment for every multihead weigher.

Other technologies

If you would like more information, start your inquiry: