Certified hygiene for MULTIPOND protein weigher

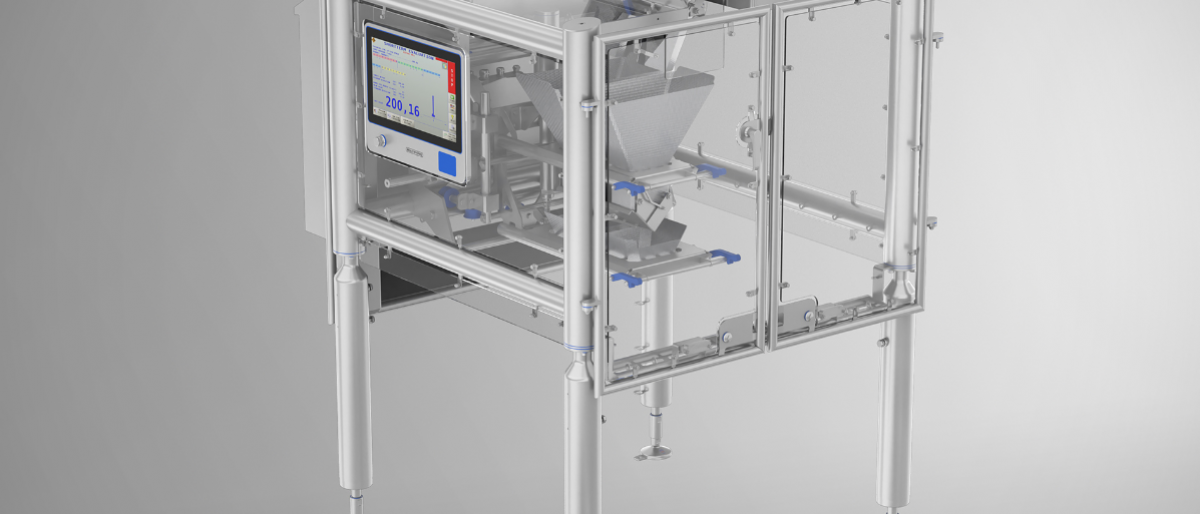

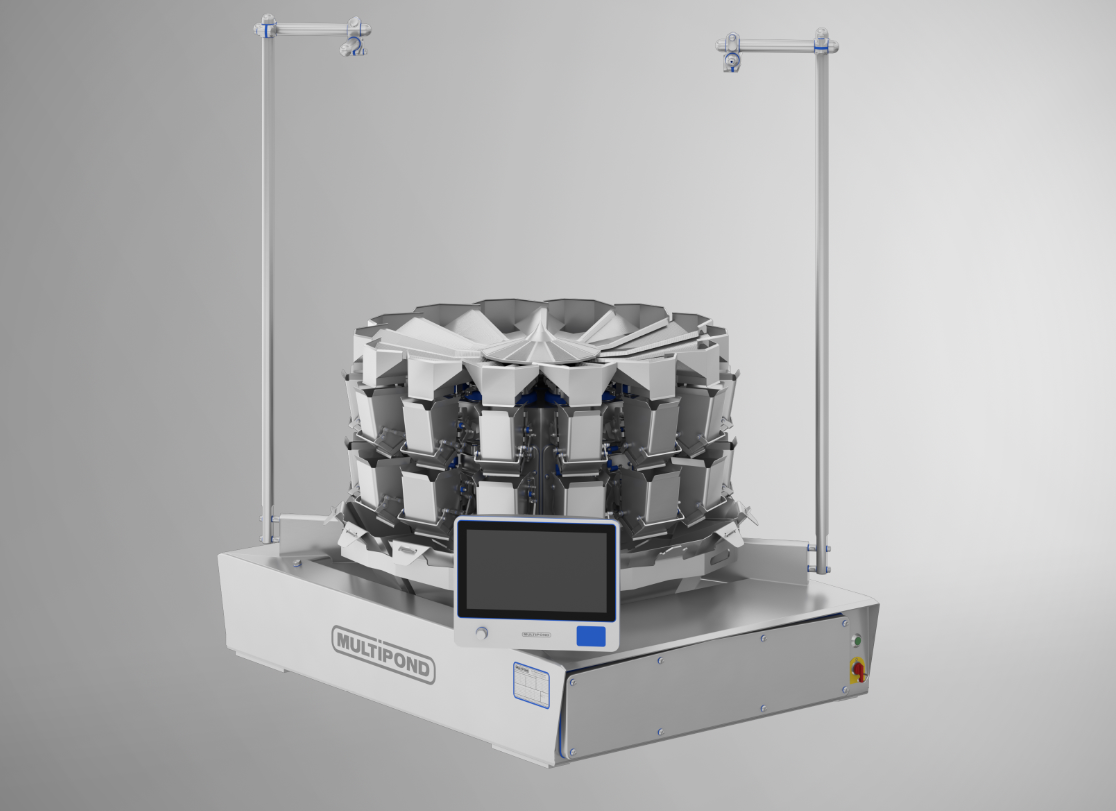

Hygiene requirements and regulations for food manufacturers are increasing almost every year and call for a swift response. Instead of developing hygienic stand-alone solutions, MULTIPOND delivers a completely hygienic solution in the form of the J Generation. The hygienically-designed MP-14-3800-1250-J multihead weigher is especially suitable for weighing meat, cheese or salad, for example.

Hygiene standards fulfilled

MULTIPOND is an active member of the European Hygienic Engineering & Design Group (EHEDG). This organization aims to achieve international hygiene standards for the manufacture and packaging of foods. The independent experts of Hygienic Design Weihenstephan (HDW) confirmed in a report that MULTIPOND hygienic multihead weighers satisfy every aspect of the extensive hygiene requirements.

Intensive research and development work enabled MULTIPOND to develop, in collaboration with HDW experts, the world’s first MP-14-3800-1250-J weighing system with the prestigious tag “Perfect hygienic design”. The HDW certificate confirming a Certified System for highly-sensitive hygiene applications was awarded by the experts.

Compliant with USDA – the American hygiene requirements

The certification for the hygienic weigher in compliance with the strict requirements of the U.S. Department of Agriculture (USDA) underlines MULTIPOND’s unwavering quest to constantly improve its product range – to the benefit of those customers who have to keep pace with ever-increasing market requirements as they process their products. With “Engineered and Manufactured in Germany” quality, high-performance technology, MULTIPOND proves once again to be in the forerunner position on the market.

All liquids, unwanted drip water for example, can be drained and collected by a specially constructed “Drip, Drop and Drain system”. The associated collecting pan can be removed and emptied without much effort. MULTIPOND has developed a hygienic channel coupling that operates without moving parts. This innovative solution has already been patented by MULTIPOND.

Exponat Interpack 2021 – the perfect configuration for the meat sector

This year, we will be showcasing at Interpack the MULTIPOND MP-14-3800-1250-J as the optimized overall solution. This includes the following aspects:

- J Generation: The entire weigher consistently fulfils Hygienic Design requirements and hence also EHEDG and USDA specifications. All materials that can potentially come into contact with food meet the requirements for materials that come into contact with food. Despite having no expensive overpressure generation function inside the weigher, in order to prevent measurement results becoming distorted, the weigher conforms to protection class IP69. As a result, it was possible to optimize the TCO.

- The patented surface structure of the distribution cone and the radially arranged feed trays improve the weigher’s product conveying characteristics. The stepped profile minimizes the contact surface between the product and cone and/or feed tray surface, which leads to lower product adherence. The product is not exposed to any additional mechanical influences, except for the usual vibration from the feed trays. In addition, the solution meets the tough hygiene requirements in the food industry. In terms of design and accessibility, both the distribution cone and the feed trays stay true to the concept of a conventional MULTIPOND multihead weigher

- ARGUS: The patented camera system guarantees a controlled, precise filling of the weigh hopper. Optimizing the product flow achieves shorter feeding times, fewer overfills and hence a greater variety of combinations. The benefit to the customer is a higher output, more accuracy and less giveaway.

- Automated metal detector check: For checking by metal detectors, MULTIPOND has developed an in-weigher system. The metallic test specimens are fed into the product flow automatically and at regular intervals. The weighing system software controls and logs the entire dumping and test process in a way that protects the results from manipulation. The magazine fill level is monitored by optical sensors. Manual errors are eliminated and maximum process reliability is achieved.

- As an upgrade to the BDE-14, the new BDE-16 operating unit is even more shock-proof and withstands impacts of up to 5 kg from a fall height of 40 cm, conforming to protection class IK10. The unit is also splash-proof (protection class IP69).

- The MiRO extension module is now able to automatically back-up data from the multihead weigher every hour outside of the operating unit. Accidentally deleted recipes, for example, can be recovered very quickly without a problem. In addition, all MULTIPOND weighing systems can be networked via the multi-function server and operated over a WLAN-capable device. This solution can also be retrofitted for older MULTIPOND systems.

MULTIPOND Wägetechnik GmbH is a highly-specialized custom machine builder for multihead weighers in the food and non-food sectors. Ever since the company was founded in 1946, the added value of weighing technology has been based on maximum precision and speed, as well as maximal product quality. The high degree of vertical integration with in-house research, design, hardware and software development at the headquarters in Germany guarantees the quality standard of this owner-managed, traditional company. All main components of the weighing system, from the load cell to the weigh hopper, are produced and precisely matched to one another during assembly. An over 300-strong, international team from Germany, France, Great Britain, The Netherlands and the USA encourages innovations and technical perfection in close cooperation with the customer.

THE LATEST NEWS