Quality seal and speed – MULTIPOND solution for sugar-coated products

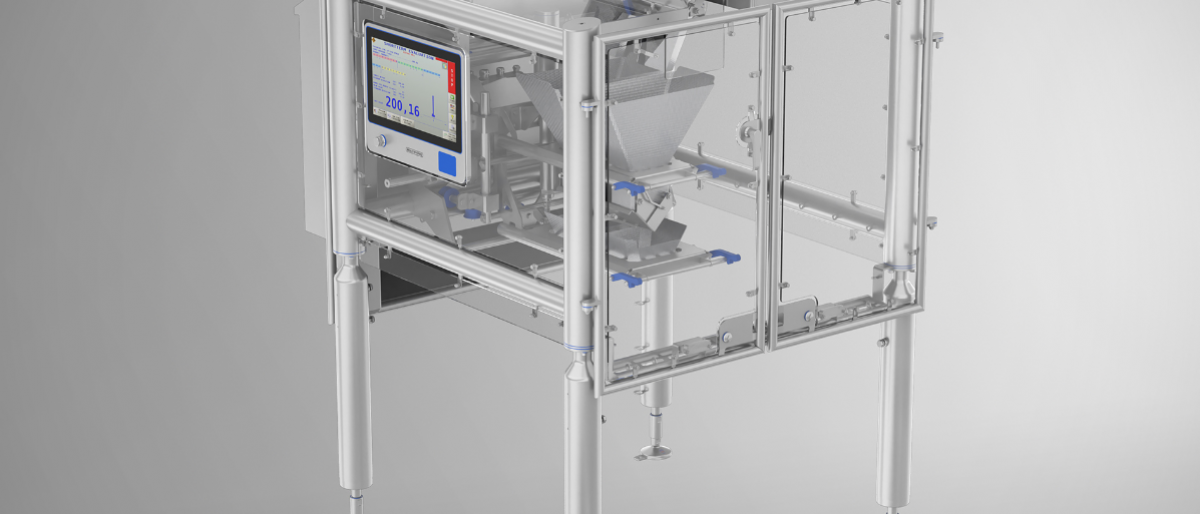

At interpack 2021, MULTIPOND will present its MP-22-1000-400-J weighing system, a complete solution for weighing sugar-coated jelly products.

High performance product handoff

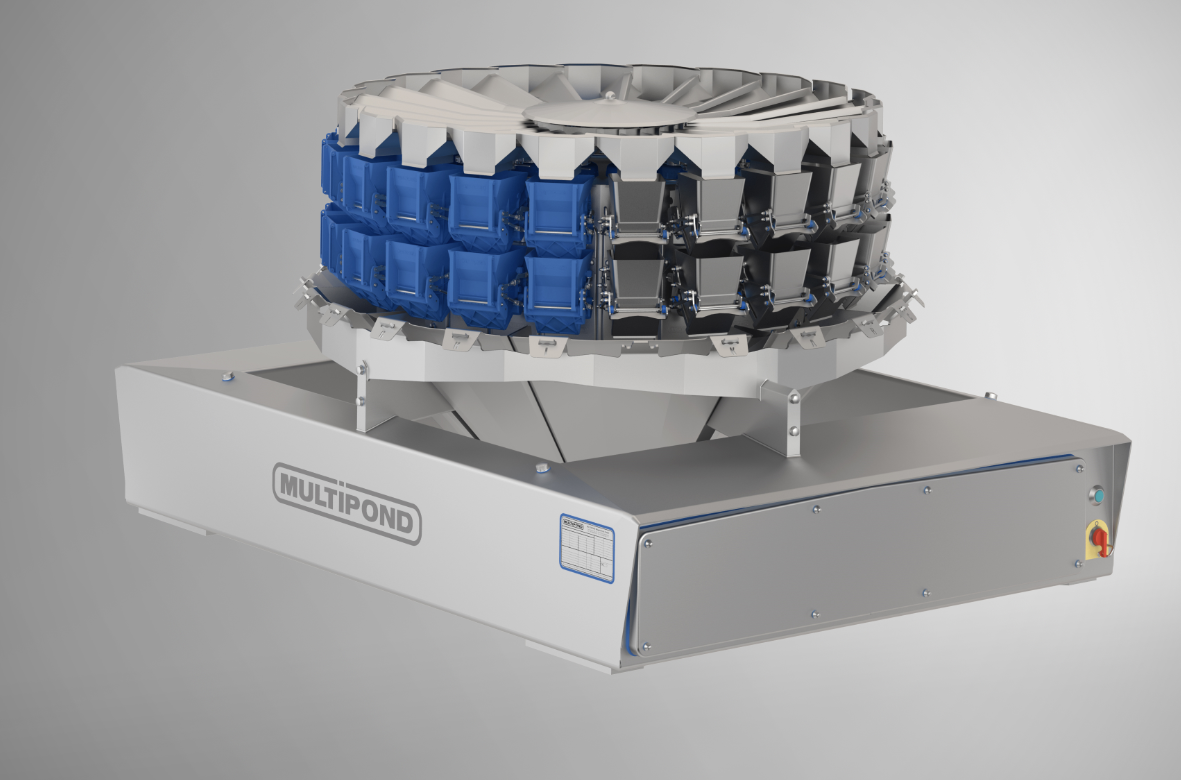

A bestseller for sugar-coated products, the MP-22-1000-400-J multihead weigher achieves 200 cycles per minute at a target weight of 200 grams. The key to maximum performance is the DSE-Q timing hopper unit. The hopper flaps have been rotated through 90 degrees compared to the predecessor model. This eliminated the transfer output limitation caused by product carryover. To minimize build-ups of the sticky product, MULTIPOND designs the meshed flaps with 3D printed stainless steel. The DSE-Q is pleasantly quiet in operation thanks to its hygienically optimized lightweight design. This solution can also be retrofitted on existing machines.

Effective fines deposition

The excess sugar around the jelly products, which dissolves on its way into the weigh hoppers due to the process technique, is channeled out of the product flow at the end of the feed trays through specially designed outlets and passed to a rotating ring-shaped collecting hopper, the so-called “evacuation ring”. This is finally removed by vacuum or by means of a plow. The sophisticated additional equipment drastically reduces loose sugar in the product flow and significantly improves the sealing quality of the downstream packaging machine.

The perfect complete solution

The MP-22-1000-400-J “jelly baby weigher” will be showcased at interpack 2021 with all its specialized features. These include two MULTIPOND innovations:

- As an upgrade to the BDE-14, the new BDE-16 operating unit is even more shock-proof and withstands impacts of up to 5 kg from a fall height of 40 cm, conforming to protection class IK10. The unit is also splash-proof (protection class IP69) and can be cleaned easily and safely thanks to the Hygienic Design.

- The MiRO extension module is now able to automatically back-up data from the multihead weigher every hour outside of the operating unit. Accidentally deleted recipes, for example, can be recovered very quickly without a problem. In addition, all MULTIPOND weighing systems can be networked via the multi-function server and operated over a WLAN-capable device.

MULTIPOND Wägetechnik GmbH is a highly-specialized custom machine builder for multihead weighers in the food and non-food sectors. Ever since the company was founded in 1946, the added value of weighing technology has been based on maximum precision and speed, as well as maximal product quality. The high degree of vertical integration with in-house research, design, hardware and software development at the headquarters in Germany guarantees the quality standard of this owner-managed, traditional company. All main components of the weighing system, from the load cell to the weigh hopper, are produced and precisely matched to one another during assembly. An over 300-strong, international team from Germany, France, Great Britain, The Netherlands and the USA encourages innovations and technical perfection in close cooperation with the customer.

THE LATEST NEWS