“This system is spot on”

The new transfer system from MULTIPOND solves a tricky packaging problem

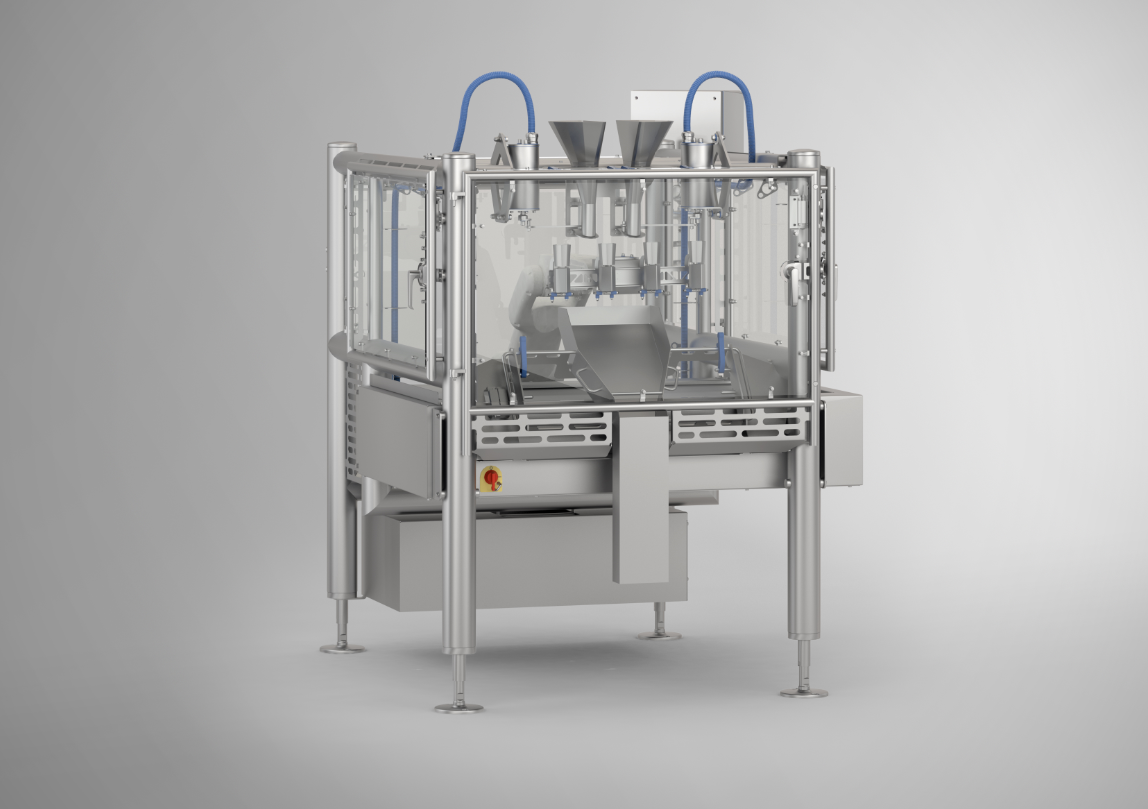

The packaging of long products such as salt sticks or dowels continues to present major challenges. The weighing of these types of product is one thing, but to place the portions aligned straight in the packaging through a fully-automated process is another. To achieve this, MULTIPOND has developed a breakthrough solution: A new transfer system with integrated robot technology.

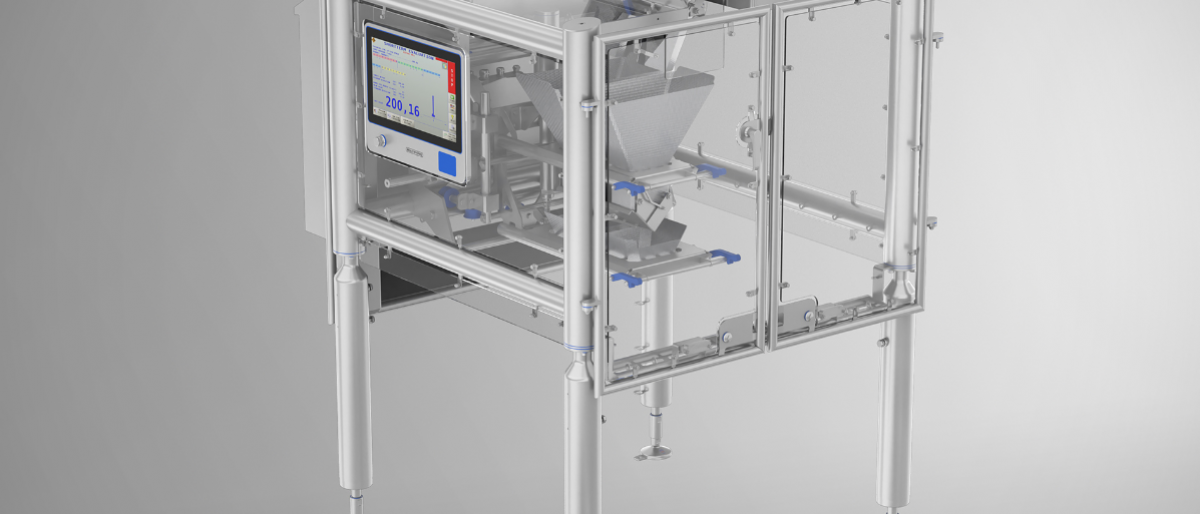

The world’s first product transfer system with integrated robot technology combined with a multihead weigher. The integrated 6-axis articulated arm robot, a fully-programmable arm that moves in all directions, uses its four-point tool to pick-up two lots of two portions from the multihead weigher at the same time and pack them neatly in the trays provided.

This used to require a highly-complex mechanism or even manual intervention. A huge benefit of the MULTIPOND transfer system is its flexibility: Each of its numerous motion sequences is freely programmable. Another plus point: The entire transfer system control is integrated into the weigher control at operator level. And compressed air is not required.

The transfer system achieves an output of up to 60 packings per minute, an absolute record for this type of product.

Ideal for use in the foot industry

The robot integrated into the system conforms to protection class IP67. All materials used are food-grade quality and very easy to clean. The system can clean itself with the appropriate device. The system is very low maintenance thanks to the simple construction.

Intelligent reactions

A 3D camera integrated into the transfer system sends information about the tray arrangement at the tray sealer to the software, which in turn initiates the required reactions. For example, if the camera detects that a tray has been positioned incorrectly or is not there at all, the four-point tool will not be filled at this position.

The first of its kind

The new transfer system for long-shaped products is MULTIPOND’s first step into robot technology. It is the company’s way of responding to market requirements. Previously, highly-complex mechanical solutions were used. During the development, MULTIPOND benefitted from its decades of experience in the construction of transfer systems. The transfer system with integrated robot technology is certainly setting a technological milestone.

MULTIPOND is an owner-managed German company. For 70 years, the company name has stood for the highest quality standards in the industrial weighing technology sector. Precision, reliability and customer orientation are anchored as maxims in the company philosophy and form the basis for innovate strength and technical perfection. The weighing systems, which are setting new standards in many sectors, are produced exclusively in Germany. In addition to its headquarters in Waldkraiburg, Germany, MULTIPOND operates subsidiaries in France, the Netherlands, England and the USA. A team of more than 250 employees pursues one aim worldwide: to provide optimum solutions for the needs and demands of customers from the food and non-food sectors.

THE LATEST NEWS