Performance counts – Why is MULTIPOND so quick?

Weighers have always needed to be accurate. Alongside accuracy, however, performance is another key factor when acquiring weighing technology.

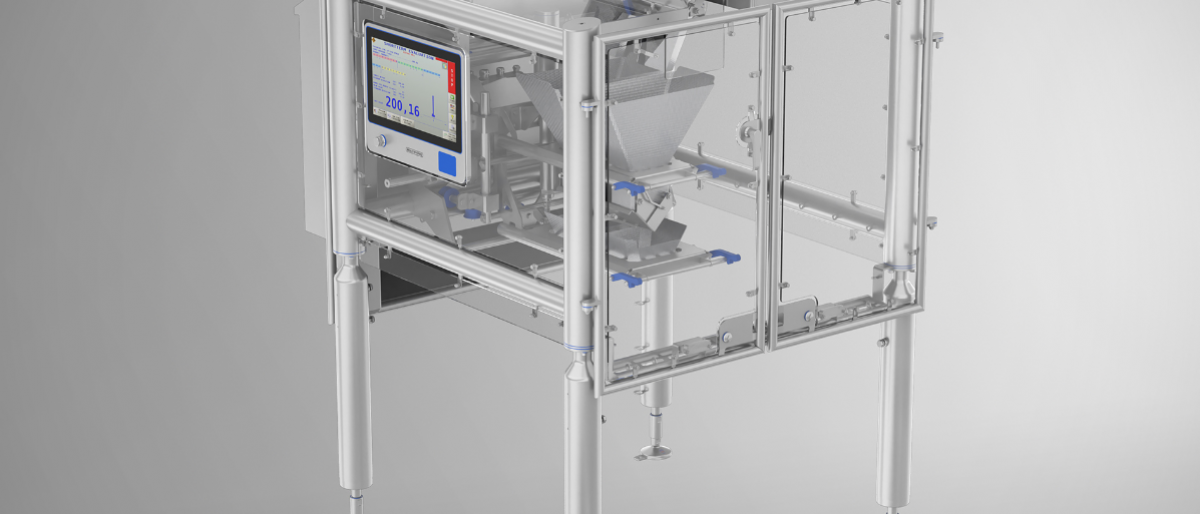

The “S5” memory weighing systems from MULTIPOND combine these two criteria. After the routine weighing process, each of the weigh hoppers fills two memory hoppers arranged beneath through specially developed swiveling funnels. The weighed partial portions are temporarily stored in these memory hoppers. The greater variety of combinations that results creates the basis for the ultimate in both precision and speed.

MULTIPOND is expanding its S5 series portfolio with the high-performance multihead weigher MP-28-400-400-J-S5. This bridges the gap between a 36-head weigher and a 36-S5 memory weigher. It is equipped with 0.4 liter hoppers and is the ideal solution for handling extremely low weights and mixture applications.

Equipped with a special product separation function, the new multihead weigher can be split into up to four segments. This makes it suitable for weighing up to four different components, such as soup ingredients, nuts, confectionary like sticky jellies and other small-sized products.

The high-speed memory weighing system achieves up to 500 weighings per minute. The 28 weigh hoppers and 56 memory hoppers achieve the highest possible portion accuracy at maximum performance through the tried and proven partial portion principle.

At these speeds, the product handling capability plays a key role – after all, the individual products or components of a product mix being weighed can sometimes be just a few grams. The load cell reliably determines the exact weight in a split second. At MULTIPOND, then, accuracy is achieved without any additional weight check, increasing the efficiency of the line even further.

The MP-28-400-400-J-S5 too is designed to meet the highest requirements even when used for wet applications. This weigher fulfils the most stringent hygiene and quality standards of the MULTIPOND J Generation:

- J Generation: The entire weigher consistently fulfils Hygienic Design requirements and hence also EHEDG and USDA specifications. All materials that can potentially come into contact with food meet the requirements for materials that come into contact with food. Despite having no expensive overpressure generation function (pneumatic) inside the weigher, the weigher conforms to the highest protection class IP69, minimizing service and maintenance costs and optimizing the TCO.

- Additional equipment can be retrofitted through a new, hygienic and patented clamp system

MULTIPOND Wägetechnik GmbH is a highly-specialized custom machine builder for weighing systems in the food and non-food sectors. Ever since the parent company ATOMA was founded in 1946, the added value of weighing technology has been based on maximum precision and speed, as well as on optimized product quality. The high degree of vertical integration with intensive research and development at the headquarters in Germany guarantees the quality standard of this owner-managed, traditional company. All main components of the weighing system, from the load cell to the weigh hopper, are produced and precisely matched to one another during assembly. An over 300-strong, international team from Germany, France, Great Britain, The Netherlands and the USA encourages innovations and technical perfection in close cooperation with the customer.

THE LATEST NEWS