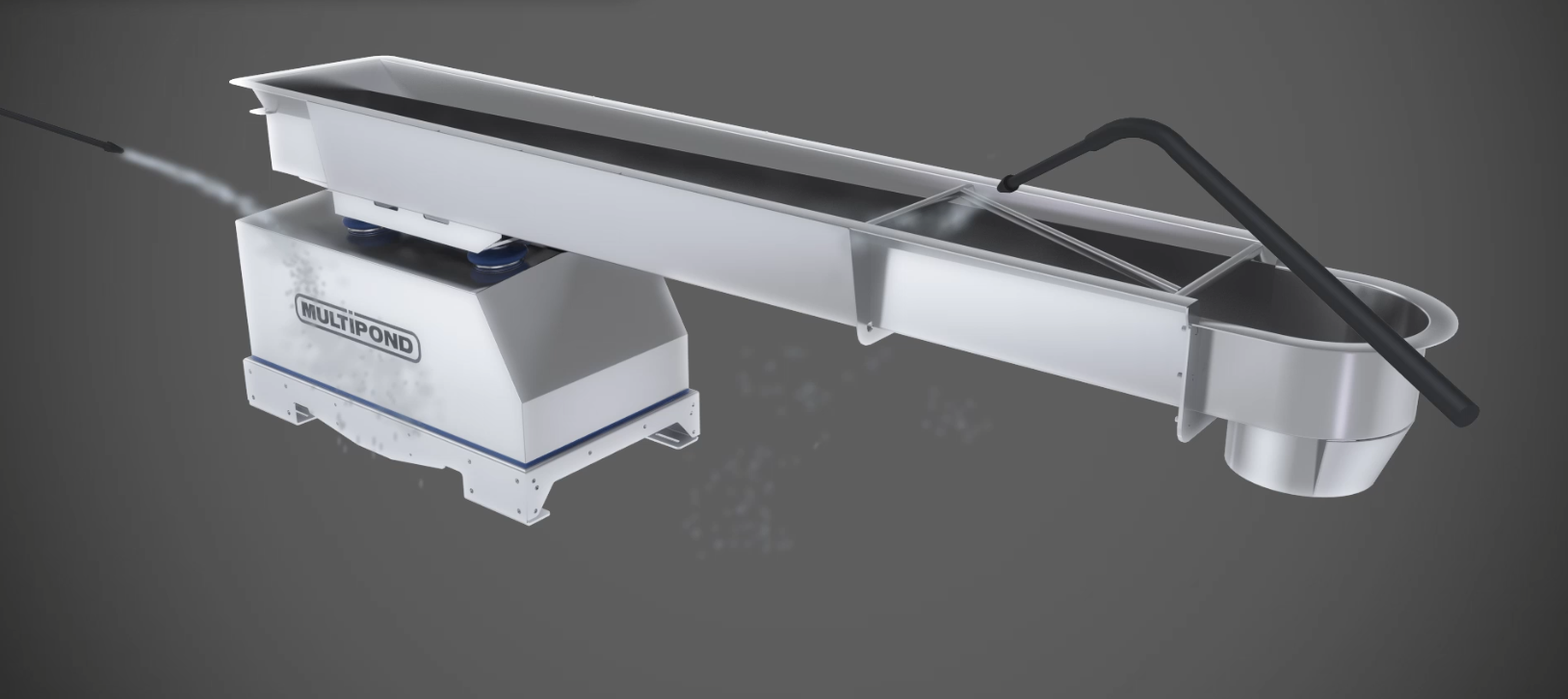

At MULTIPOND, hygiene starts with the product feed

The hygienic cross head feeder from MULTIPOND satisfies the highest hygiene requirements. This feeder is especially suitable for transporting difficult products such as meat, cheese or salad.

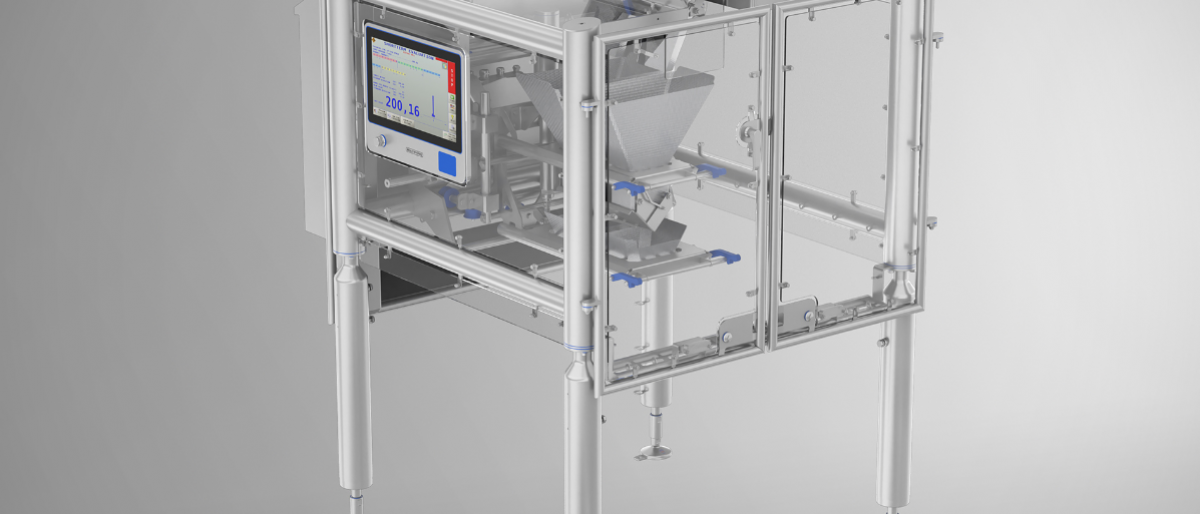

Hygienic and powerful

The hygienic cross head feeder satisfies the highest hygiene requirements for use in the food sector. The cross head feeder is designed in compliance with USDA and EHEDG Hygiene Directives and guarantees, with protection class IP69, fast and reliable cleaning.

Thanks to the optimized drive, larger product quantities can be transported and output is increased as a result. The higher counterweight creates another fundamental benefit: due to the lower dynamic force effects (vibrations) on the platform, the multihead weigher runs smoothly, and this delivers an even faster and more accurate measurement result.

Tailored to a product’s characteristics

The MULTIPOND project team works with the customer to configure a suitable cross head feeder. The following parameters play a role here:

- Dimensions: The cross head feeder can be produced in a number of versions to meet the different throughput requirements

- Surface finish: Depending on product composition, MULTIPOND can choose from a number of different surface finishes to systematically influence the conveying properties

- Special version: Cross head feeder troughs can be equipped with fines deposition or sugar deposition, water separation or noise reduction features in order to meet product-specific requirements

MULTIPOND Wägetechnik GmbH is a highly-specialized custom machine builder for multihead weighers in the food and non-food sectors. Ever since the company was founded in 1946, the added value of weighing technology has been based on maximum precision and speed, as well as maximal product quality. The high degree of vertical integration with in-house research, design, hardware and software development at the headquarters in Germany guarantees the quality standard of this owner-managed, traditional company. All main components of the weighing system, from the load cell to the weigh hopper, are produced and precisely matched to one another during assembly. An over 300-strong, international team from Germany, France, Great Britain, The Netherlands and the USA encourages innovations and technical perfection in close cooperation with the customer.

THE LATEST NEWS