High-speed weigher – In the fast lane with 900 weighings per minute

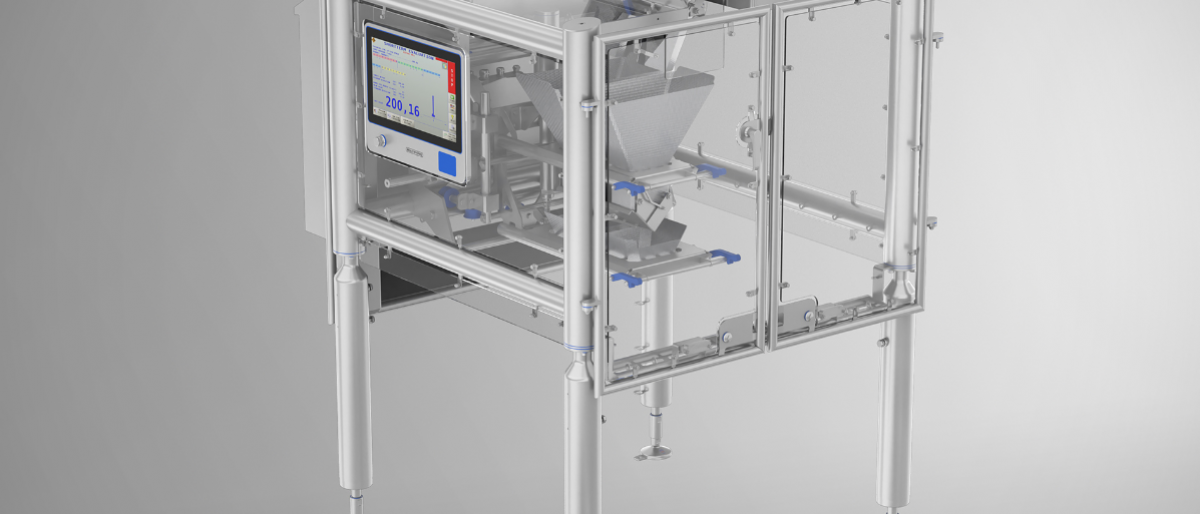

The MULTIPOND MP-36-400-400-J-S5 weighing system continues to lead the field in the weighing of small-sized products and for mixture applications.

The high-speed memory weighing system achieves up to 900 weighings per minute. 36 weigh hoppers and 72 memory hoppers achieve the highest possible measuring accuracy at maximum speed through the tried and proven partial quantity principle.

At interpack 2021, the weighing system will be equipped with two MULTIPOND innovations:

- As an upgrade to the BDE-14, the new BDE-16 operating unit is even more shock-proof and withstands impacts of up to 5 kg from a fall height of 40 cm, conforming to protection class IK10. The unit is also splash-proof (protection class IP69).

- The MiRO extension module is now able to automatically back-up data from the multihead weigher every hour outside of the operating unit. Accidentally deleted recipes, for example, can be recovered very quickly without a problem. In addition, all MULTIPOND weighing systems can be networked via the multi-function server and operated over a WLAN-capable device. This solution can also be retrofitted for older MULTIPOND systems.

Soup ingredients, nuts or jelly babies – fast product change without using tools

Up to six distribution cone segments make the weigher the ideal choice for mixture applications of small-sized products, such as cereals in yoghurt cartons. MULTIPOND customers can remove, clean and reinstall these segments using the practical quick-clamping system in the fastest time without needing tools. This allows a fast product changeover in compliance with the existing hygiene regulations.

High speed with MULTIPOND accuracy consistently achieved

The MP-36-400-400-J-S5 also consistently fulfils the highest hygiene and quality standards of the MULTIPOND J Generation weighing technology:

- J Generation: The entire weigher consistently fulfils Hygienic Design requirements and hence also EHEDG and USDA specifications. All materials that can potentially come into contact with food meet the requirements for materials that come into contact with food. Despite having no expensive overpressure generation function inside the weigher, in order to prevent measurement results becoming distorted, the weigher conforms to protection class IP69. As a result, it was possible to optimize the TCO.

- Additional equipment can be retrofitted through a new, hygienic and patented clamp system

MULTIPOND Wägetechnik GmbH is a highly-specialized custom machine builder for multihead weighers in the food and non-food sectors. Ever since the company was founded in 1946, the added value of weighing technology has been based on maximum precision and speed, as well as maximal product quality. The high degree of vertical integration with in-house research, design, hardware and software development at the headquarters in Germany guarantees the quality standard of this owner-managed, traditional company. All main components of the weighing system, from the load cell to the weigh hopper, are produced and precisely matched to one another during assembly. An over 300-strong, international team from Germany, France, Great Britain, The Netherlands and the USA encourages innovations and technical perfection in close cooperation with the customer.

THE LATEST NEWS