FachPack 2021

Weighed into the future with MULTIPOND.

MULTIPOND will present two innovative solutions at the FachPack trade fair in Nuremberg from 2021-09-28 to 201-09-30.

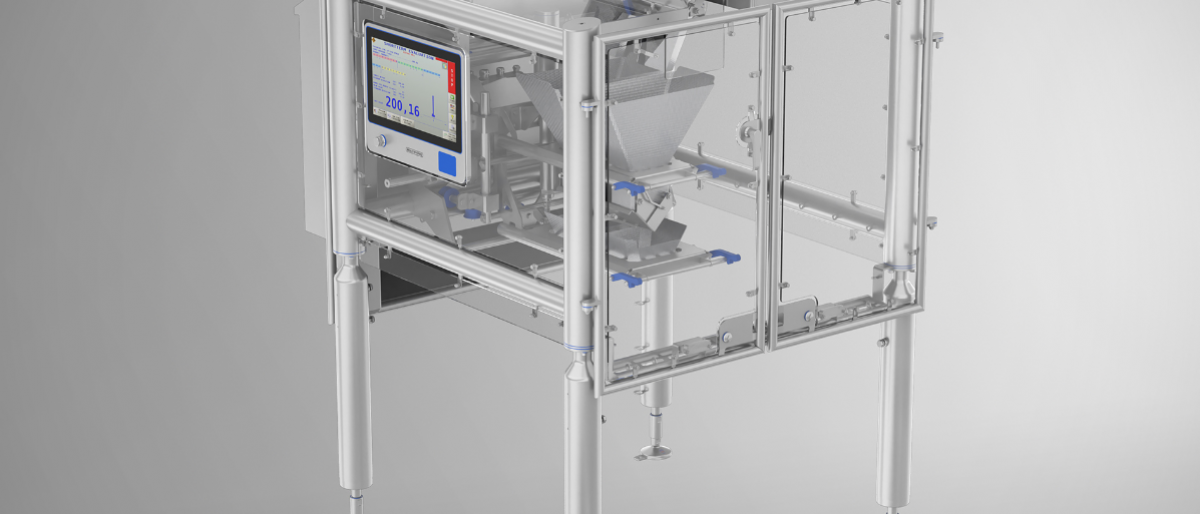

A fully automated linear multihead weigher designed for the gentle handling of sensitive foods will be making its debut.

Flexible production solution in the smallest space coupled with maximum efficiency.

In terms of design and accessibility, this weigher resembles the concept of a conventional MULTIPOND multihead weigher. The drop heights within the product feed and product handoff have been reduced to an absolute minimum thanks to the linear design. The linear multihead weigher is also equipped with a specially developed handoff unit. This consists of counter-running conveyor belts with a centrally arranged timing hopper. In this way, the product is handed off to the packaging machine from a centered position. The space-saving weigher achieves an output of up to 60 weighings per minute and can be integrated into a packaging line at any time. It is well suited for weighing products that require gentle conveying due to their characteristics and cannot, therefore, be weighed using conventional multihead weighers. These are mainly brittle and easily breakable products such as fresh fruit, pastries or coated chocolate buttons. The new linear multihead weigher also conforms to the established hygiene standards of the Multipond J Generation, thereby fulfilling EHEDG and USDA requirements. The Hygienic Design guarantees simple and safe cleaning.

The MULTIPOND stand will also showcase the perfect integrated solution for weighing sugar-coated jelly products: the MP-22-1000-400-J with all its special features.

High performance product handoff

A bestseller for sugar-coated products, the multihead weigher achieves 200 cycles per minute at a target weight of 200 grams. The key to maximum performance is the DSE-Q timing hopper unit. The hopper flaps have been rotated through 90 degrees compared to the predecessor model. This eliminated the transfer output limitation caused by product carryover. To minimize build-ups of the sticky product, MULTIPOND designs the meshed flaps with 3D printed stainless steel. The DSE-Q is pleasantly quiet in operation thanks to its optimized lightweight design. This solution can also be retrofitted on existing machines.

Effective fines deposition

The excess sugar around the jelly products, which dissolves on its way into the weigh hoppers due to the process technique, is channeled out of the product flow at the end of the feed trays through specially designed outlets and passed to a rotating ring-shaped collecting hopper, the so-called “evacuation ring”. In this ring, the fines are removed by vacuum or by means of a plow. The sophisticated additional equipment drastically reduces loose sugar in the product flow and significantly improves the sealing quality of the downstream packaging machine.

Eyes for your weigher – ARGUS-3D CAMERA SYSTEM

The advantages of a camera-monitored weigher are clear to see: higher accuracy, improved performance, less giveaway and ultimately significantly reduced costs. Thanks to the automated response to the 3D image data, the patented camera system guarantees controlled filling of the weigh hopper. An optimized product flow means that the trays on the weigher are uniformly occupied and, as a result, the product is optimally distributed. Overfills can be avoided, as the fluctuations that occur during product feed are equalized by the self-optimizing process. The result is a greater variety of combinations, even for products that are difficult to convey such as salad ingredients, cheese or meat. Consequently, there is no need to intervene in the feeding process. This reduces the risk of unhygienic contamination.

MULTIPOND Wägetechnik GmbH is a highly-specialized custom machine builder for weighing systems in the food and non-food sectors. Ever since the company was founded in 1946, the added value of weighing technology has been based on maximum precision and speed, as well as on optimized product quality. The high degree of vertical integration with intensive research and development at the headquarters in Germany guarantees the quality standard of this owner-managed, traditional company. All main components of the weighing system, from the load cell to the weigh hopper, are produced and precisely matched to one another during assembly. An over 300-strong, international team from Germany, France, Great Britain, The Netherlands and the USA encourages innovations and technical perfection in close cooperation with the customer.

THE LATEST NEWS