Tried and proven timing hopper concept even more efficient

“The timing hopper is a transverse double duck mouth”

A 90 degree rotation makes the tried and tested timing hopper concept even more efficient

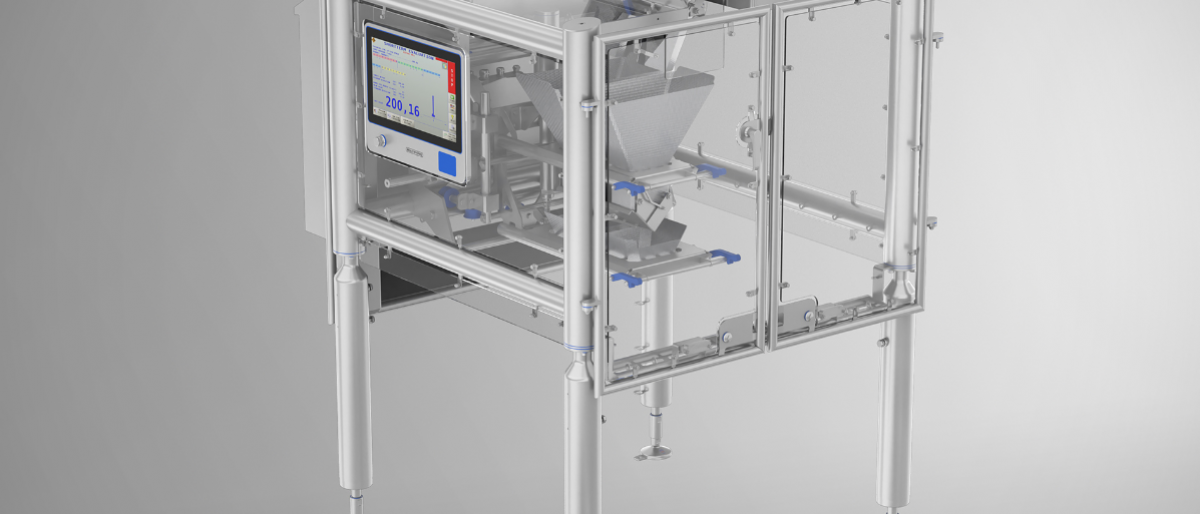

The experienced MULTIPOND engineers have further optimized the transfer process between weigher and tubular bag machine. MULTIPOND was already at a massive advantage on the market with its proven system, the patented double duckmouth. This system has now been further developed. Rotating the patented double duckmouth through 90 degrees now permits speeds of up to 25 percent faster.

Thanks to the new timing hopper concept, the transverse double duckmouth (DSEQ), the multihead weighers from MULTIPOND now crack a magical limit: with a target weight of 200 grams, up to 200 weighings per minute are possible.

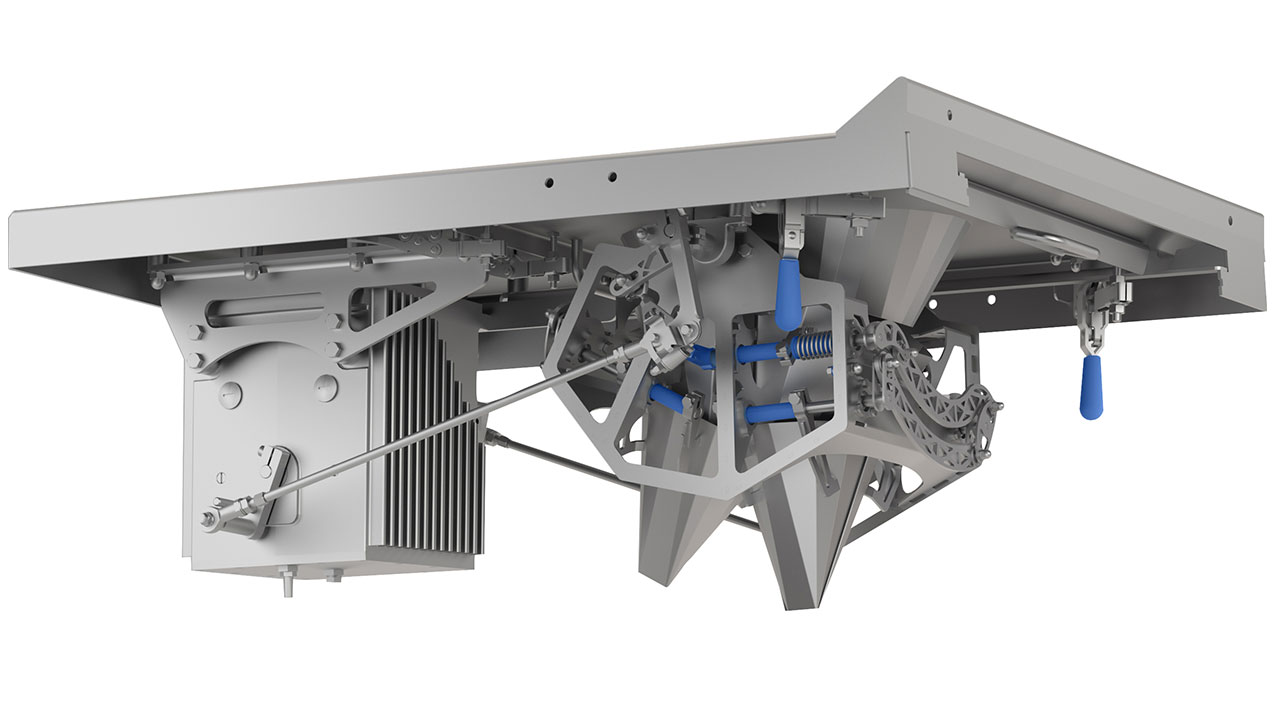

The prerequisite was met by re-aligning the timing hopper with the beak-shaped outlet, to which the product transfer system owes its name. Because the double duckmouth is now at a different angle to the weigher, the timing hopper can continue immediately after dumping the product, thereby allowing the second chamber to be emptied quicker. With the previous model, there is a time delay, albeit minimal, at this point – the system continues only when the product has been completely dropped from the hopper.

The DSEQ works more efficiently and, due to its lightweight construction, also somewhat quieter. With the effective further development of the patented timing hopper concept, MULTIPOND underpinned once again its leading position as an innovative company – and the willingness to continuously improve.

Refinement of a proven concept for extremely sticky products

For the design of the duckmouth flaps, MULTIPOND is now using 3D laser-sintered meshed flaps made from titanium for extremely sticky products. These meshed flaps minimize the contact surface between the product and flaps, and this reduces product adherence.

MULTIPOND is an owner-managed German company. For 70 years, the company name has stood for the highest quality standards in the industrial weighing technology sector. Precision, reliability and customer orientation are anchored as maxims in the company philosophy and form the basis for innovate strength and technical perfection. The weighing systems, which are setting new standards in many sectors, are produced exclusively in Germany. In addition to its headquarters in Waldkraiburg, Germany, MULTIPOND operates subsidiaries in France, the Netherlands, England and the USA. A team of more than 200 employees pursues one aim worldwide: to provide optimum solutions for the needs and demands of customers from the food and non-food sectors.

THE LATEST NEWS