MULTIPOND – always one step ahead – unique solution for the quick and reliable packing of tube pack bags

A growing trend: narrow, long bags, slightly larger than a chocolate bar, the so-called tube packs. Small and convenient, ideal as a snack between meals – now an increasingly important part of everyday life for everyone. And also the so-called “100 calories packs”, small portions for restricted calorie intake. More and more food producers are following this trend. As a result, an increasing number of products, such as jelly babies, nuts, dried fruits, various cereals, are being offered in these kinds of packs.

As a marketing concept, it’s hard to imagine supermarkets or gas stations without these products, often placed close to the checkout – yet this presents an immense challenge to packaging technology. With vertical bag machines, we are often at the limits of technology. Due to the small diameter of the format tube, blockages (congestion) at high speeds are commonplace. As a result, such packaging systems are often not very productive.

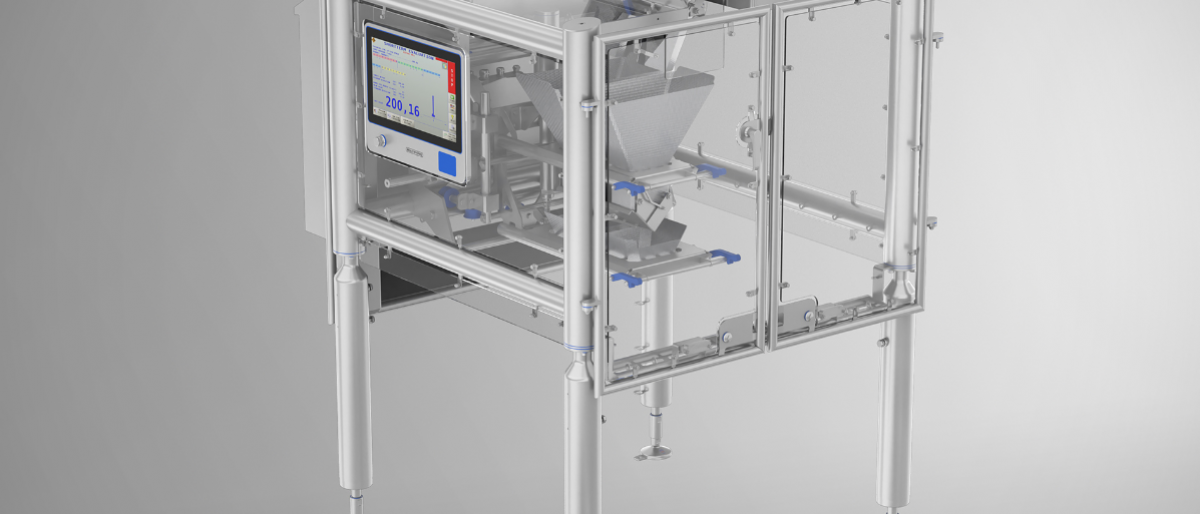

To solve this problem, MULTIPOND has developed a new patented timing hopper concept, once again demonstrating its position as a leading innovator of multihead weighers. The aim was to pre-format the portions to prevent blockages in the filling funnel of the packaging machine.

To be able to pre-format the product, the diameter of the timing hopper corresponds to the diameter of the format tube of the tubular bag machine. A special mechanism on the timing hopper opens the flaps, while increasing the diameter of the timing hopper frame. This enables the pre-formatted product to be transferred quickly and reliably into the form fill seal machine. Permitting target weights of up to 100 g at an output of up to 110 weighings per minute.

MULTIPOND has been an owner-managed German company since the very beginning. Drawing on more than 65 years’ experience in industrial weighing technology, we are a pioneer in this sector. Our success is based on the high quality and technical standard of our weighing systems. We consciously commit to a high level of vertical integration, as well as production exclusively in Germany. Customer focus has become our corporate maxim. A team of more than 200 employees commits worldwide to offer our customers from the food and non-food sectors optimized, unique solutions tailored exactly to their requirements at all times.

Sales, project planning and service are handled by the headquarters in Germany, by the four subsidiaries in France, the Netherlands, England and the USA, and by a worldwide network of agents.

THE LATEST NEWS