Your partner for

confectionery

Our strengths – the benefits to you

- Improved product pattern – We offer various solutions for separating loose fines, sugar and so on, and this improves the appearance of the products inside the packaging.

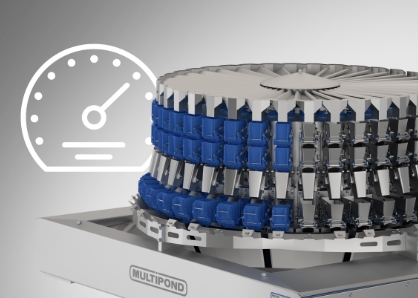

- Timing hopper DSE Q – The unique new concept for the timing hopper (DSEQ) is now able to achieve outputs of 200 and more cycles/minute with a target weight o 200g.

- Meshed flaps –Soft, sticky products are difficult to weigh. The use of meshed flaps minimizes the contact surface between product and flap, which in turn increases output and efficiency.

- High speed – Our systems show their potential and benefits especially in high-speed applications. Whether fast signal processing, special software, adaptive filters or special timing hoppers – all processes are geared towards increasing output.

- Precise counting – The counting function is stored in every multihead weigher with MULTIPOND. By using our special variants with reject, MULTIPOND can even guarantee individual ejection without loss of cycle times and automatically return incorrect portions according to type.

- Exact mixes – The weighing of product mixes is one of our core competencies. With this hardware and software feature, we guarantee precise mixing ratios in terms of piece and weight.

- Unmatched versatility – Our systems are always adapted to your application and can still be changed. Should the conditions or products change, machine equipment, formats or software can be adjusted at any time.

- Individual, tailor-made transfer solutions – We design and develop individual transfer systems for every product and the most varied forms of packaging.

“Good support in terms of service and engineering, first-class reliability and system availability translate into a total package, which makes for a good partner.”

Herbert Mederer, owner and Managing Director at Mederer

Our weighers in action

Take a look at the projects we have already implemented and see for yourself. From jelly babies to lollipops to candies – benefit from the experience and knowledge we have developed over decades.

Our solutions to meet your requirements

If you would like more information, start your inquiry: